RFID (Radio Frequency Identification) technology has become a game-changer in supply chain management, especially in the retail industry. By enabling businesses to track their inventory in real-time with precision and efficiency, RFID technology is revolutionizing the way companies manage their supply chains. In this blog post, we will explore the benefits of RFID technology in inventory tracking, examine real-world applications through case studies, discuss challenges and considerations for implementing RFID technology, and look towards the future of supply chain management with the widespread adoption of RFID technology.

Benefits of RFID Technology in Inventory Tracking

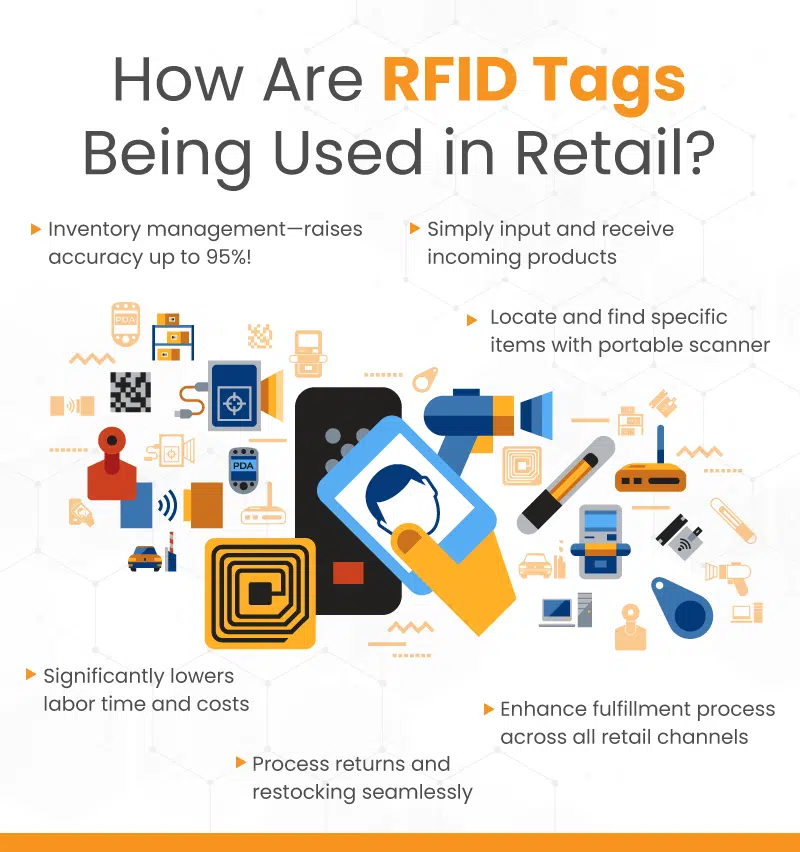

One of the key advantages of RFID technology in inventory tracking is the increased accuracy and efficiency it provides. Unlike traditional barcode systems, RFID tags do not require a line of sight to be read, allowing for quicker and more reliable tracking of inventory items. This leads to improved inventory management, reduced out-of-stock situations, and enhanced customer satisfaction.

Furthermore, RFID technology offers real-time data visibility, enabling businesses to monitor their inventory levels and locations instantaneously. This leads to better decision-making and improved operational efficiency as companies can proactively manage their supply chain based on up-to-date information.

In addition to accuracy and real-time visibility, RFID technology helps reduce manual errors and labor costs associated with inventory tracking. By automating the tracking process, businesses can streamline their operations and allocate resources more effectively, leading to cost savings and increased productivity.

Case Studies: Real World Applications of RFID Technology

Example 1: A leading retail giant implemented RFID technology in their stores and warehouses, resulting in a significant improvement in inventory management. By using RFID tags on merchandise, the company was able to reduce out-of-stock situations by 30% and increase sales by 5% within the first year of implementation.

Example 2: In the pharmaceutical industry, RFID technology has played a crucial role in combating counterfeit drugs and improving traceability in the supply chain. By implementing RFID tags on drug packages, pharmaceutical companies can verify the authenticity of medications and track their movement from production facilities to pharmacies, ensuring patient safety and regulatory compliance.

Example 3: An automotive manufacturer revolutionized their production process by incorporating RFID tags on components and finished products. By tagging each part with a unique identifier, the manufacturer could track the assembly process in real-time, identify bottlenecks, and optimize production flow. This resulted in a 15% increase in production efficiency and a 20% reduction in defects.

Challenges and Considerations for Implementing RFID Technology

While RFID technology offers numerous benefits, its implementation can pose challenges for businesses. One of the primary considerations is the upfront cost of RFID hardware and software, which may deter some companies from adopting the technology. However, it is important to conduct a thorough ROI analysis to assess the long-term cost savings and operational efficiencies that RFID technology can provide.

Image courtesy of koronapos.com via Google Images

Another consideration is data privacy and security concerns associated with RFID technology. As RFID tags transmit data wirelessly, there is a risk of unauthorized access or data breaches. Businesses need to implement robust security measures, such as encryption and access controls, to protect sensitive information stored on RFID tags.

Integration with existing systems and processes is another challenge for businesses looking to implement RFID technology. Companies need to ensure that their current infrastructure can support RFID technology and that employees are adequately trained to use the new system effectively. Change management and employee buy-in are crucial for successful RFID implementation.

The Future of RFID Technology in Supply Chain Management

Looking ahead, RFID technology is poised to continue transforming supply chain management with advancements in tag technology, read ranges, and durability. Smaller and more durable RFID tags will enable businesses to track smaller items and withstand harsh environmental conditions, expanding the applications of RFID technology beyond traditional inventory tracking.

Beyond inventory tracking, RFID technology has the potential to revolutionize other aspects of supply chain management, such as asset tracking, access control, and customer engagement. By leveraging RFID technology in these areas, businesses can enhance operational efficiency, improve security, and provide a more personalized customer experience.

In conclusion, RFID technology is reshaping the way businesses manage their supply chains, offering unprecedented visibility, efficiency, and accuracy in inventory tracking. As the technology continues to evolve, businesses that embrace RFID technology will be better positioned to adapt to the changing landscape of retail and supply chain management. By staying informed and exploring the potential of RFID technology, companies can stay ahead of the curve and drive innovation in their industry.