In today’s rapidly evolving business landscape, supply chain logistics plays a crucial role in ensuring timely deliveries, minimizing costs, and achieving customer satisfaction. As the world embraces the Internet of Things (IoT), a paradigm shift is taking place in the logistics industry. Leveraging the power of IoT, businesses are revolutionizing their supply chain processes, ultimately leading to enhanced efficiency, real-time visibility, and improved decision-making capabilities. This feature aims to explore the significant role of IoT in optimizing supply chains and its impact on the logistics industry.

The Power of IoT in Supply Chain Optimization

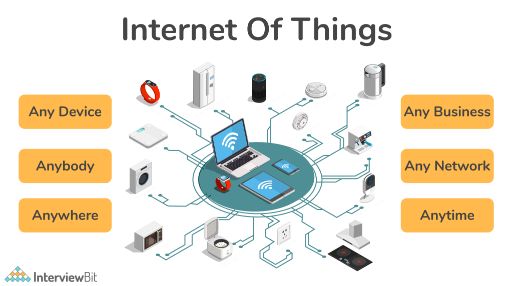

Defining Internet of Things (IoT)

The Internet of Things (IoT) refers to a network of physical devices, vehicles, and other objects embedded with sensors and connected to the internet. These devices collect and exchange data, enabling seamless communication and actionable insights.

IoT-enabled Sensors and Devices in Logistics

The integration of IoT involves equipping logistics assets, such as vehicles, containers, and warehouses, with sensors and connected devices. These IoT-enabled tools capture and transmit real-time data on location, condition, and other relevant parameters.

Key Benefits of IoT Integration in Supply Chains

By harnessing the power of IoT, businesses gain several benefits in optimizing their supply chains:

- Real-time visibility of assets

- Efficient inventory management

- Enhanced demand forecasting accuracy

- Seamless last-mile delivery

- Improved security and quality control

Real-Time Data: The Key to Seamless Logistics Management

Tracking and Monitoring Goods in Transit with IoT Devices

IoT-connected devices, such as GPS trackers and sensors, allow businesses to track the precise location, movement, and condition of goods in transit. Real-time data on temperature, humidity, and shock ensures that perishable or fragile items can be monitored to maintain their quality and integrity.

Warehouse Optimization with IoT-enabled Inventory Management Systems

IoT sensors integrated within warehouses provide real-time visibility on stock levels, location, and storage conditions. This data enables businesses to optimize warehouse layout, streamline picking and packing activities, and reduce inventory holding costs.

Real-Time Alerts and Notifications for Improved Delivery Precision

With IoT, businesses can receive real-time alerts and notifications related to shipment status, delays, or potential issues. This information allows for proactive measures to be taken, ensuring that deliveries are on track and any potential disruptions are addressed promptly.

Predictive Analytics for Demand and Inventory Management

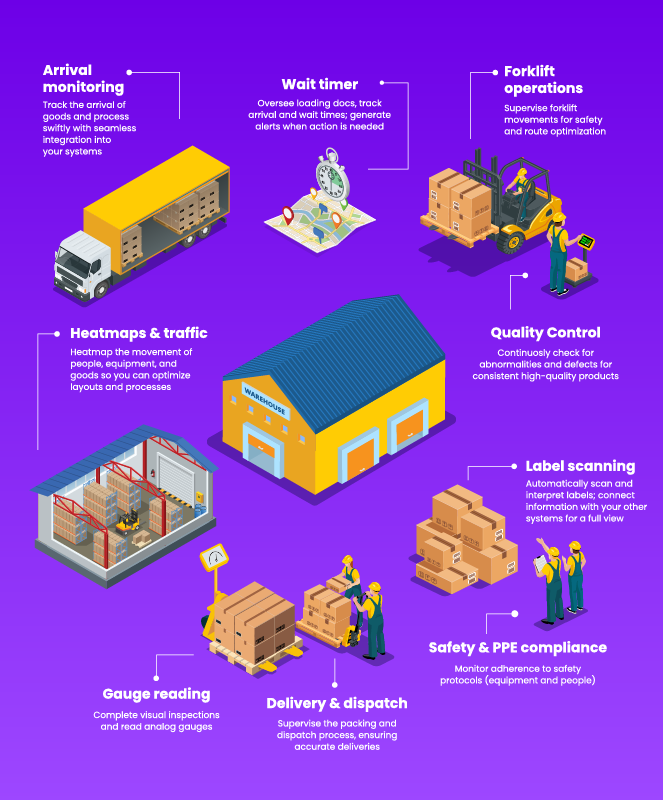

Image courtesy of kibsi.com via Google Images

Enhancing Demand Forecasting Accuracy with IoT-generated Data

IoT-generated data, combined with advanced analytics, enables businesses to gain deep insights into customer demand patterns. This data can be used to forecast demand more accurately, improving inventory planning and minimizing stockouts or overstocking.

Dynamic Inventory Control and Efficient Replenishment

IoT-enabled sensors can monitor inventory levels in real-time. This data, combined with predictive analytics, allows businesses to optimize inventory control and automate the replenishment process. It ensures that the right products are available at the right time, minimizing both stockouts and excess inventory.

Reducing Stockouts and Overstocking through Predictive Analytics

Predictive analytics helps businesses identify patterns and trends that may lead to stockouts or overstocking situations. By analyzing historical sales data, market trends, and external factors, businesses can make data-driven decisions to avoid stockouts, minimize inventory holding costs, and reduce waste.

Streamlining Last-Mile Delivery with IoT

Enhancing Route Optimization and Delivery Tracking

IoT-enabled tracking devices and route optimization algorithms allow businesses to streamline last-mile delivery operations. Real-time updates on traffic conditions, customer location, and optimized routes enable efficient and on-time deliveries.

Improving Customer Experience through Real-Time Delivery Updates

By leveraging IoT, businesses can provide their customers with real-time updates on delivery status, estimated arrival times, and delivery notifications. This level of transparency and communication enhances customer experience and improves satisfaction.

Reducing Delivery Failures and Returns with IoT-enabled Tracking Systems

IoT-based tracking systems help reduce delivery failures and subsequent returns. With real-time tracking, businesses can proactively address delivery challenges, resolve issues, and avoid customer dissatisfaction.

Ensuring Supply Chain Security and Quality Control

Enhancing Traceability and Authentication with IoT-enabled Sensors

Image courtesy of prosglobalinc.com via Google Images

IoT sensors can be used for traceability and authentication purposes. For example, in the food industry, sensors can monitor the temperature and conditions of perishable items throughout the supply chain, ensuring compliance with food safety regulations and providing transparency to consumers.

Preventing Losses from Theft, Damage, or Spoilage

IoT-enabled security measures, such as surveillance cameras, GPS tracking, and tamper-proof packaging, help prevent losses from theft, damage, or spoilage. If any unusual activity is detected, immediate alerts can be sent to relevant parties to mitigate risks.

Collaborative Efforts for Proactive Quality Control

With IoT, multiple stakeholders in the supply chain, including manufacturers, distributors, and retailers, can collaborate on quality control measures. Real-time data sharing and analysis allow for quick identification and resolution of any issues that may arise, ensuring product quality and safety.

Overcoming Challenges: IoT Implementation in Logistics

Infrastructure Requirements and Connectivity Issues

One of the main challenges in IoT implementation is the need for robust infrastructure and seamless connectivity. Businesses must invest in reliable networks, IoT devices, and scalable platforms to ensure the smooth transmission and analysis of data.

Ensuring Data Privacy and Cybersecurity

As IoT involves the collection, transmission, and storage of sensitive data, businesses must prioritize data privacy and cybersecurity. Implementing encryption protocols, secure data storage, and access control mechanisms are crucial for safeguarding information.

Workforce Training and Integration of IoT Systems

The successful adoption of IoT in logistics requires the training and upskilling of the workforce. Employees should be equipped with the necessary knowledge and skills to operate and leverage IoT-enabled devices effectively. Additionally, integrating IoT systems with existing logistics infrastructure and workflows may require careful planning and coordination.

In Conclusion

As the logistics industry evolves to meet ever-increasing consumer demands, optimizing supply chains with the Internet of Things has become imperative. Embracing IoT technologies empowers businesses to gain real-time visibility into their logistics operations, facilitating informed decision-making, reducing costs, and enhancing customer satisfaction. However, successful implementation requires addressing challenges, investing in infrastructure, and ensuring data security. By harnessing the transformative power of IoT, logistics companies can unlock efficiencies and establish a competitive edge in the dynamic world of supply chain management.